Biltong Company Customises Pouches with Offline Barcode Printing System

Improved Efficiency and Reduced Packaging Costs

Cruga, part of the MeatSnacks Group, is Europe’s largest biltong producer. It processes between eight and nine tonnes of fresh beef silverside every week, supplying around eight million bags of biltong each year to the major supermarket retailers. It also packs Jerky for its partner company, The Jerky Group.

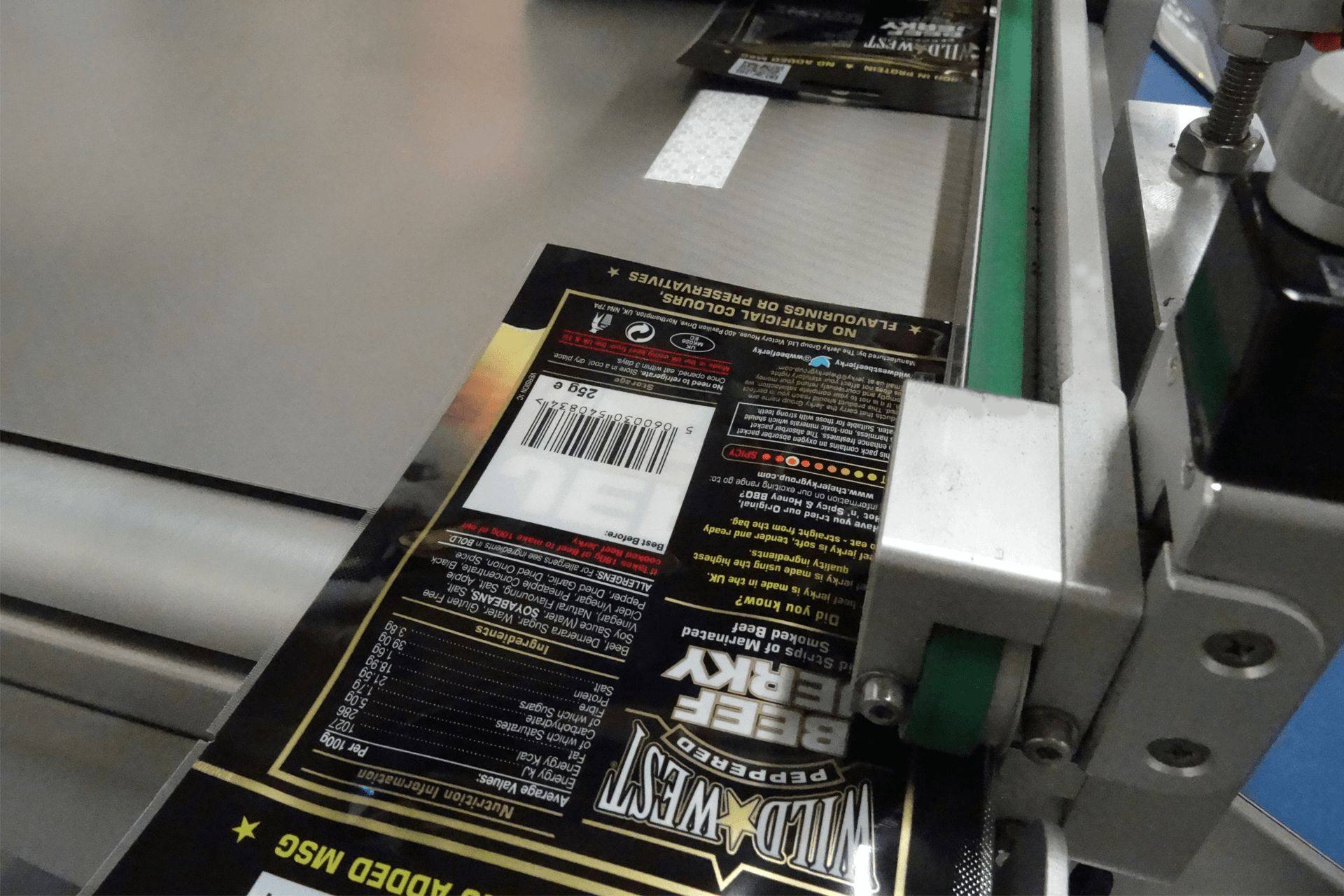

An offline barcode printing system comprising a udaFORMAXX feeding system, fitted with an ICE Zodiac thermal transfer printer is helping the company to improve production efficiency and reduce packaging costs.

Change From Vertical Form Fill Seal to Pouches

Cruga Biltong was founded in 1998 when owner, David Low, started producing premium biltong to an authentic South African recipe. Since then, the biltong market has evolved from a South African niche area to a significant segment of the UK meat snacks market.

In 2014, Cruga took the decision to put its product into pouches, replacing its Vertical Form Fill & Seal (VFFS) packaging machines with two pouch fillers provided by its long-term machinery supplier.

Company founder, David Low, explains this change in packaging: “When you pack Biltong, you need to remove oxygen from the pack to maintain quality. With the VFFS, we started with flat film that was converted into a bag with three sealed edges and that was vulnerable to faults. We also felt that the finished pack was less attractive than pouches which also had the advantage of only having to seal one end.”

Reducing Packaging Costs

To reduce packaging costs, Cruga uses a range of generic pouches that it overprints with a barcode and data denoting product-specific information. This gives it the flexibility to respond to changes in customer orders while minimising wastage.

We needed a separate printer that would allow us to convert our generic packaging for specific products.

David Low

When using the VFFS system, Cruga was able to print this information on to the film prior to filling. David explains: “With the change in packaging machinery, it was not possible to do this. We could print date, batch and time information with inkjet printers integrated in the pouch fillers, but barcodes could not be printed to the standard required. We needed a separate printer that would allow us to convert our generic packaging for specific products.”

Offline Coding is the Answer

The company opted for a standalone feeding system with ICE Zodiac Thermal Transfer printer supplied by specialist offline coding company, PrintSafe. David explains: “Our Engineering Manager found the udaFORMAXX and visited PrintSafe. They successfully tested a range of pouch types and sizes. He was also impressed by the build quality and simplicity of operation.”

The udaFORMAXX is available with two different feeding mechanisms – a narrow belt-grip or wide conveyor belt. Cruga opted for the narrow-belt udaFORMAXX ‘i’ model where the pouches are fed past the thermal transfer printer using a tight grip belt conveyor to ensure that there is no pouch movement. In addition, the udaFORMAXX ‘i’ stops briefly so that the pouch is stationary at the moment of printing, increasing accuracy and reducing wear on the print head.

Add to this the build quality and ease of use and you have a top quality printer unit that can print thousands of pouches per hour with virtually no rejects and operated by one operator.

David Low

David says: “These two factors made all the difference. The machine gripped the pouch firmly along one side and printed while stationary. Add to this the build quality and ease of use and you have a top quality printer unit that can print thousands of pouches per hour with virtually no rejects and operated by one operator.”

Cruga Biltong initially purchased one udaFORMAXX, wanting to confirm that speed and accuracy would be maintained within the actual production environment.

Fast and Reliable Barcode Printing

PrintSafe supplied the system fitted with an ICE Zodiac thermal transfer printer. “The speed is phenomenal,” says David. “The feeders are fast and reliable. Alongside the feeding mechanism and build quality, there are countless other benefits. One of these is the ease-of-use of the ICE Zodiac thermal transfer printer. Our non-English-speaking operators have absolutely no problem running the machines. My experience with other thermal transfer printers is that you need a PHD in maze solving just to change the ribbon. With the ICE Zodiac, you just drop the ribbon spool in and off you go.

The feeders are fast and reliable. Alongside the feeding mechanism and build quality, there are countless other benefits.

David Low

Cruga Biltong initially purchased one udaFORMAXX, wanting to confirm that speed and accuracy would be maintained within the actual production environment.

PrintSafe supplied the system fitted with an ICE Zodiac thermal transfer printer. “The speed is phenomenal,” says David. “The feeders are fast and reliable. Alongside the feeding mechanism and build quality, there are countless other benefits. One of these is the ease-of-use of the ICE Zodiac thermal transfer printer. Our non-English-speaking operators have absolutely no problem running the machines. My experience with other thermal transfer printers is that you need a PHD in maze solving just to change the ribbon. With the ICE Zodiac, you just drop the ribbon spool in and off you go.

Confident in the long-term performance, Cruga placed an order for a second unit. David says: “Our operators are extremely happy. With the udaFORMAXX, wastage is negligible and I am confident that one operator can comfortably run two printers.”