alphaJET CIJ for Airflo Fishing

Airflo Fishing manufactures award-winning fly lines at its factory in Brecon, South Wales. The company has developed and perfected its fly line production technique over nearly 30 years and produces the world’s only range of 100% PVC-free lines. It exports its fly lines as far afield as the US, New Zealand and Japan.

Specialist small character inkjet printer

Airflo produces hundreds of fly line varieties with different breaking strains and different cores. It uses an alphaJET continuous inkjet (CIJ) from PrintSafe to print product identification details on each line.

The alphaJET pico (now available as the alphaJET 5 SP) is a specialist continuous inkjet designed for printing in narrow spaces such as on optical fibre or small components. The 42 µm nozzle, along with the printer software, delivers a clear print, even at the minimum text height of 0.7mm.

alphaJET pico CIJ print height from 0.7 – 10mm

Excellent print quality

Airflo Purchasing Manager, Gareth Jones, found PrintSafe’s website when looking for a replacement for an existing printer that was causing issues and costly downtime. He explains, “I was looking for an inkjet coder that would print small text on our narrow diameter fly lines and came across PrintSafe and the alphaJET printers. Their samples team produced lots of print samples to test quality and contrast on different colours and thicknesses of lines. The print was really clear; a lot sharper than we had been used to before.”

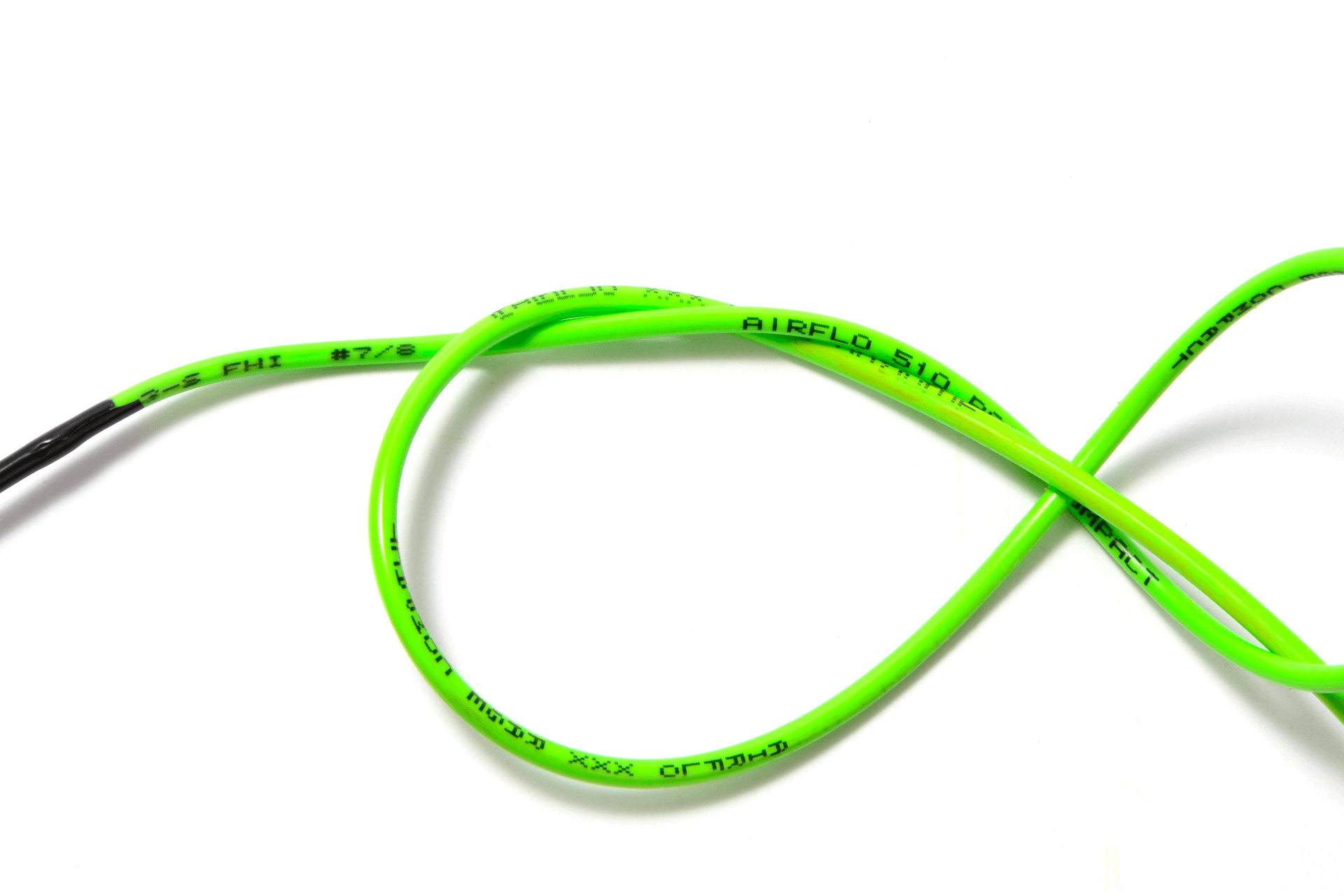

Following ink testing, PrintSafe specified a black abrasion-resistant ink to ensure good contrast and adhesion on the fly lines. The black ink shows up clearly on the brightly coloured lines – including on orange, yellow, blue and green

The print was really clear; a lot sharper than we had been used to before

Many hundreds per day

Airflo operates three extruding lines for producing the fly lines with a polyurethane-based coating around a central core. The fly lines are made in a continuous process and put onto large diameter drums for curing.

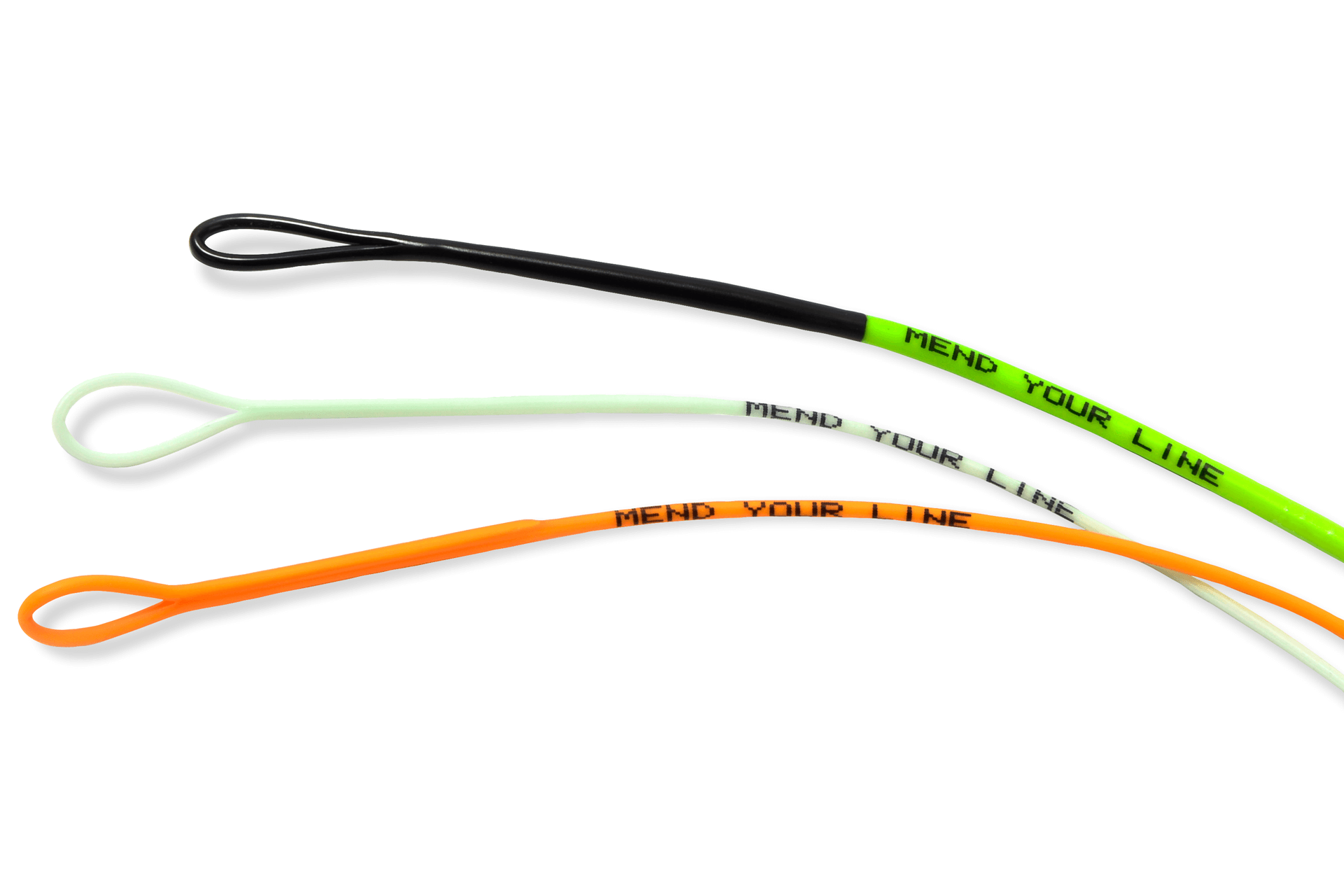

Once the lines are cured, they are taken to the spooling station to create smaller hand-sized coils that are eventually packed into the fly line box. A loop is welded onto the end of each line.

The ID is printed next to the welded loop, right at the tip of the line making it easy to see without having to pull the line off the reel. We print hundreds and hundreds a day in batches of different variants; it’s simple and quick, including setting up the print messages using the printer touchscreen.”

Print positioned next to welded loop

Next, printing on dark substrates

Gareth Jones is working with PrintSafe to test using a white ink version of the alphaJET. He says, “We are looking at purchasing a second printer. We are really happy with the way the black ink looks and now want to explore adding the same product identification information onto our black and darker coloured lines.”

Gareth concludes, “The printer has proved straightforward and reliable. We’d definitely recommend PrintSafe for both the machinery and the buying experience.”