EU Plant Passport Printing Directly on Plant Pots

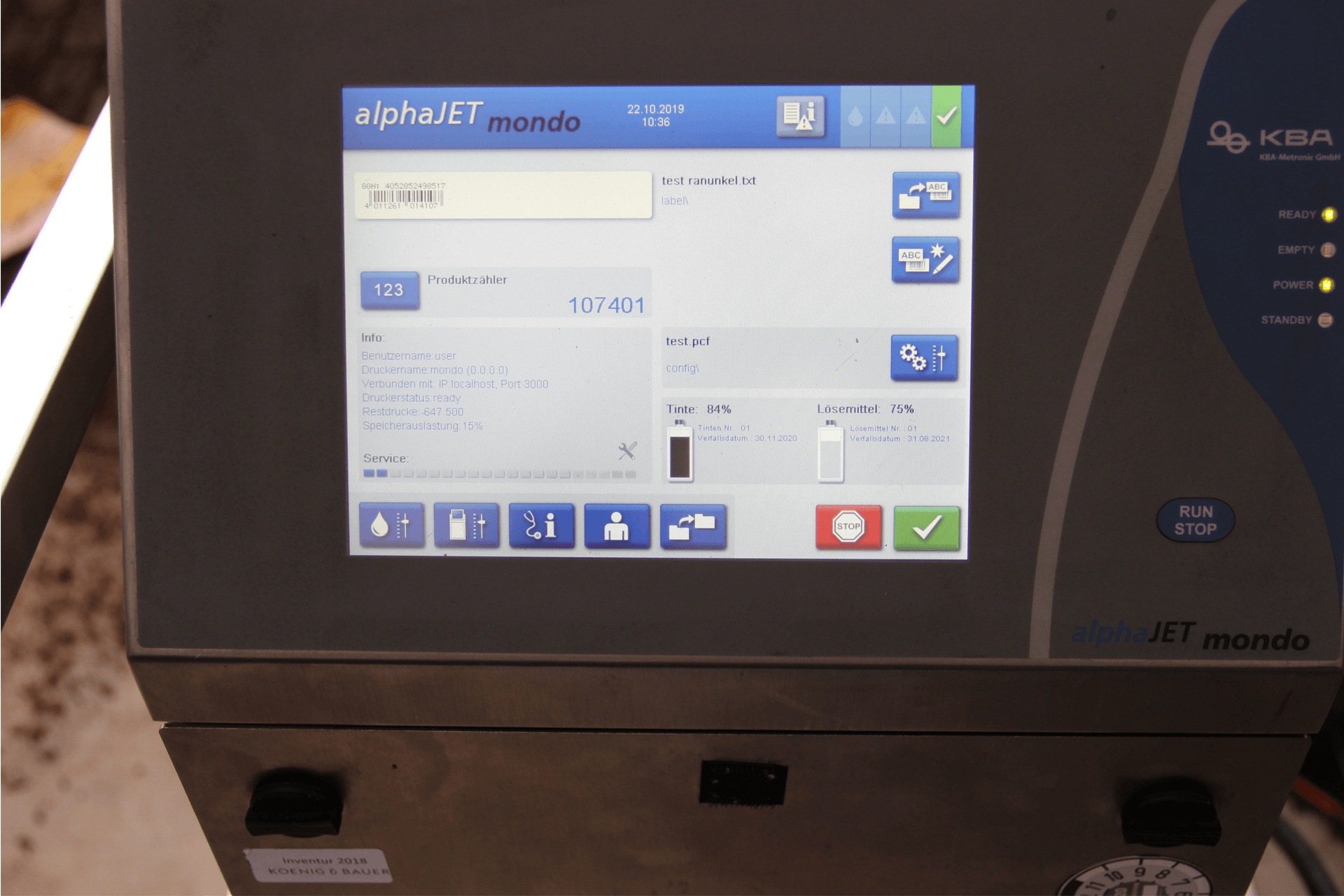

alphaJET Continuous Inkjets for Plant Passport Printing

The EU plant Health Regulation Regulation 2016/2031/EU (PHR) requires plant growers in Europe to provide plant passport information for all plant products intended for planting sold within the EU.

German company, Topfpflanzen Velmans, produces more than three million potted plants a year in its 4.4 ha glasshouse facility in North Rhine-Westfalia. It is using alphaJET continuous inkjet printers from Koenig & Bauer Coding to print EU plant passport information and barcodes directly onto plant pots.

Sustainable Approach

Velmans uses non-plastic biodegradable plant pots as part of its commitment to sustainability. Printing the required plant passport directly on the pots avoids the use of plastic labels.

What’s more, removing the need to buy and store large numbers of labels will deliver cost savings and a quick return on the investment in two alphaJET continuous inkjets.

Added Value for Trading Partners

By installing an alphaJET continuous inkjet printer on either side of a conveyor belt, Velmans can print the plant passport and an EAN13 machine readable barcode at the same time.

The pot filling process determines conveyor speed and throughput. At around 8000 pots per hour, the alphaJET printers still have plenty of capacity.

With the addition of Code-M software, the team at Velmans can create print images on a PC in the office, rather than at the printer location. Operators on the line, select the correct print image using a hand-held barcode scanner. The printer then loads all of the correct parameters for that job. Changeover between varieties is very quick and the risk of the wrong print is removed.

Easy Changeover Between Varieties

With the addition of Code-M software, the team at Velmans can create print images on a PC in the office, rather than at the printer location. Operators on the line, select the correct print image using a hand-held barcode scanner. The printer then loads all of the correct parameters for that job. Changeover between varieties is very quick and the risk of the wrong print is removed.

We are very satisfied with our solution. The daily maintenance effort for the printers is around 1 minute. Because we can now prepare and save the print images in a quiet environment on the PC. Misprints have dropped to zero. We now not only produce in a more environmentally friendly way, but also in a more cost-saving way.