Koenig & Bauer Coding Partners with Ceramics R&D Company for Heat Resistant Marking

Koening & Bauer Coding GmbH, manufacturer of the alphaJET continuous inkjets supplied by PrintSafe, recently partnered with a ceramics R&D company to provide a solution for printing on industrial ceramic components.

Ceramic materials are used in a wide range of industries for their heat, wear, and corrosion resistant properties. Part of the production process involves sintering, where the raw mass is heated to 1450°C to create a strong, vitrified material.

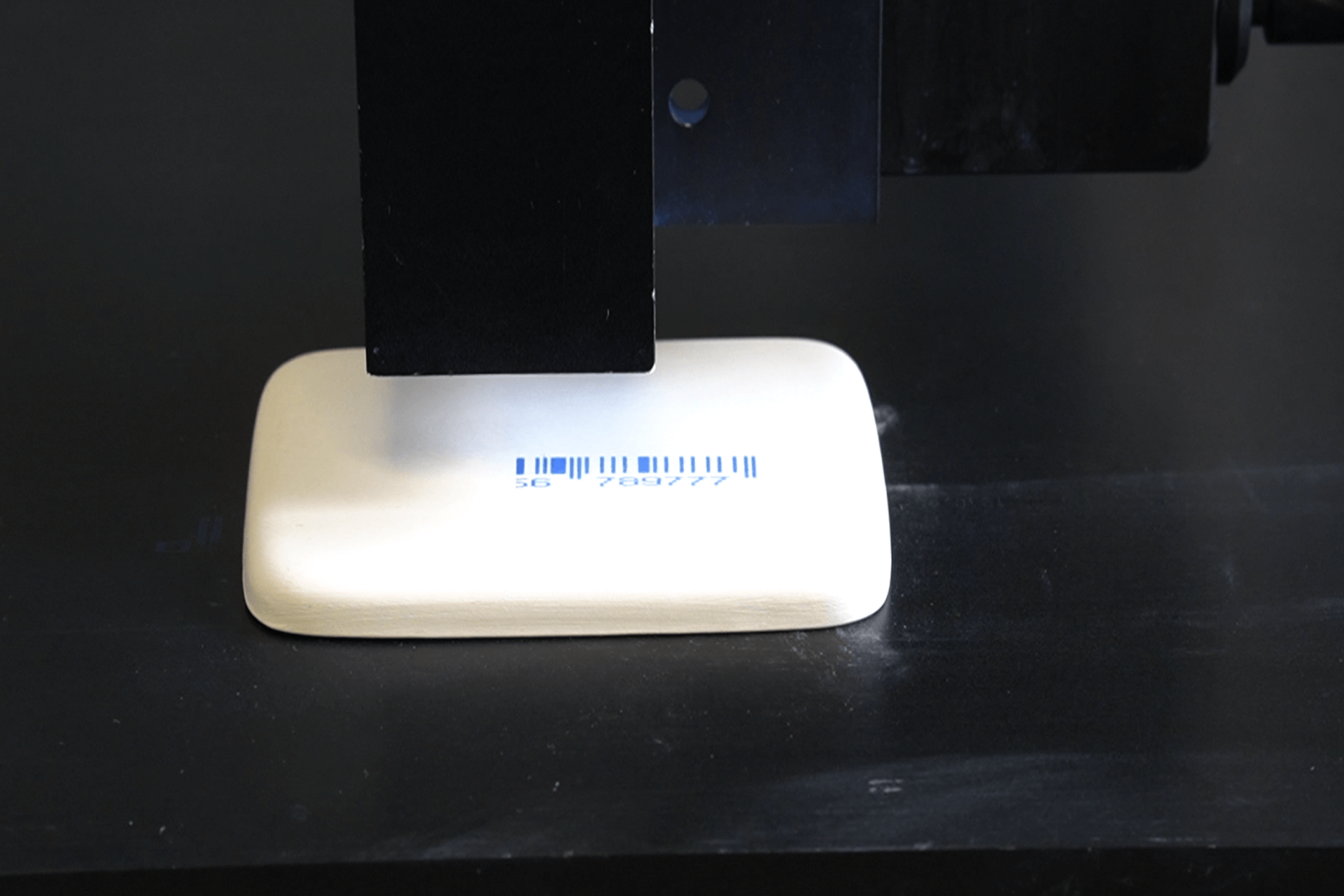

In this project with WZR ceramic solutions GmbH, Koenig & Bauer Coding supplied an alphaJET continuous inkjet for printing 2D and 3D barcodes as well as alphanumeric text. The printer uses an ink called CerTrace®, specially developed by WZR to withstand the heating process.

The printer is positioned over a small hand-transport table which slides the component under the print head. The printed codes are clearly readable before and after sintering.