Date Coder Rental Helps Enterprising Dairy Company

From a Few Hundred to 33,000 Bottles Per Week

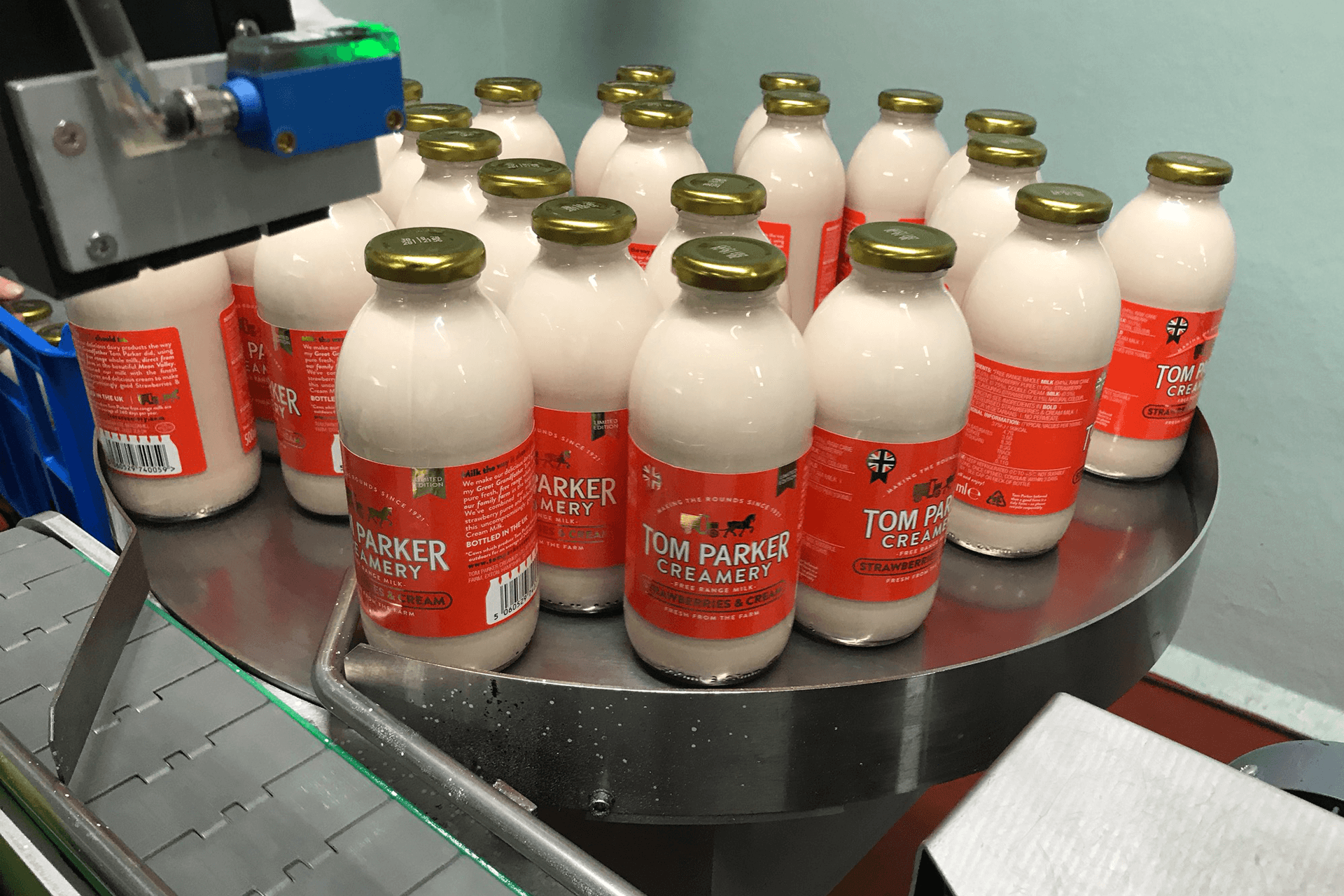

Three years ago, Tom Parker Creamery’s founder Jack Martin spotted an opportunity for premium flavoured milks. He re-established his Great Grandfather’s Tom Parker Dairy brand and started by selling a few hundred bottles of flavoured milk a week at local food festivals and farmers’ markets. Fast-forward just three years and the creamery now supplies Milk & More and Sainsbury’s, and is gearing up for Christmas production numbers of 33,000 bottles per week.

Bold Ambitions

Tom Parker Creamery has a strong family farming heritage and a clear focus on quality ingredients. Thanks to Managing Director Rob Yates and his team, the creamery also has bold ambitions for its range of flavoured milks and cream. Glass bottles give a nod to tradition but imaginative flavour combinations, alongside passion and hard work, are driving the company forward.

Renting something, knowing it works and then rolling that into a rent-to-buy option has worked well for us.

Rob Yates

Managing Director

Rental Flexibility

As Yates explains, balancing growth ambitions and the cashflow needed can be a challenge. He says, “We’re a start-up business that has been able to nudge forward with the support of our shareholders. Even so, making capital machinery investments can be nerve-wracking. You’re putting significant investment into a machine and you’re not certain until it’s in place whether it’s going to work as you need it to.”

The option to rent an inkjet date coder from PrintSafe meant that Yates could try before buying. He says, “Renting something, knowing it works and then rolling that into a rent-to-buy option has worked well for us.”

Growth During Lockdown

Doorstep delivery company, Milk & More, is Tom Parker Creamery’s main customer. During the Covid-19 lockdown period in spring and summer 2020, people were either unable or reluctant to go to supermarkets and the demand for doorstep deliveries went “through the roof”. The increase in demand for the company’s flavoured milks meant finding ways to speed up production.

When PrintSafe first installed the alphaJET inkjet coder it was on an automatic labeller in a low-care area of the factory. The machine printed a 2-line date and batch code in black onto the labels as they were applied to the filled bottles.

The printer and labeller are now on a conveyor in the main production area. Bottles no longer need to be moved in crates before they can be labelled and coded. Instead, an automated line takes bottles from a dry store for filling, capping, labelling and then coding.

Coding is now sorted. We print onto the caps, the code looks great and the ink adheres well.

Process Change

Yates says, “When we changed the production line, we also moved to printing directly onto the bottle caps rather than on the label. PrintSafe tested various inks for us and we eventually opted for a white ink for contrast on our black or gold caps.” He adds, “Because we were renting, we were able to change from a dye-based printer to a pigmented ink printer without having to buy a second machine. PrintSafe loaned us a printer initially and then put in a new one once we knew we were happy with the approach.”

The next step for Rob Yates is to install a second filling machine in time for Christmas production volumes. He says, “Coding is now sorted. We print onto the caps; the code looks great and the ink adheres well. Now I’m looking at a new filler, which is a significant capital investment. There are more exciting developments to come in 2021.”

He concludes, “The support we’ve had from PrintSafe has been exceptional. I would say that they have been one of the best, if not the best supplier that we’ve had in the three years since setting this up.”